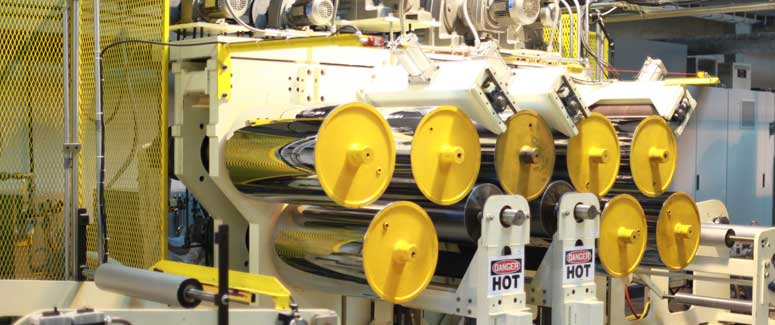

Biax now has lab sheet extrusion capabilities to offer, enhancing our current biaxial orientation capabilities. In March of 2013 Biax installed a ZSK-25 Krupp Werner & Pfleiderer 25mm twin screw, co-rotating extruder. This extruder feeds a casting/calendering vertical 3 roll stack. Material can be wound after extrusion, or fed straight to the Biax MDO line.

Featured Capabilities:

- 25mm co-rotating screws.

- 40:1 L/D.

- AC motor and vector drive 10:1 constant torque over base speed range.

- 2.5 ratio gearbox for screw speed to 1200 RPMs.

- Electric barrel heaters and a cooling manifold for heating and cooling in a controlled manner.

- 9 barrel sections and 10 heating zones.

- Liquid injection capabilities.

- Temperature controlled vertical 3-roll stack.

Calendering/Casting Unit:

Calendering/Casting Unit:

- Clutch driven, variable speed wind-up unit, utilized if only extrusion is required.

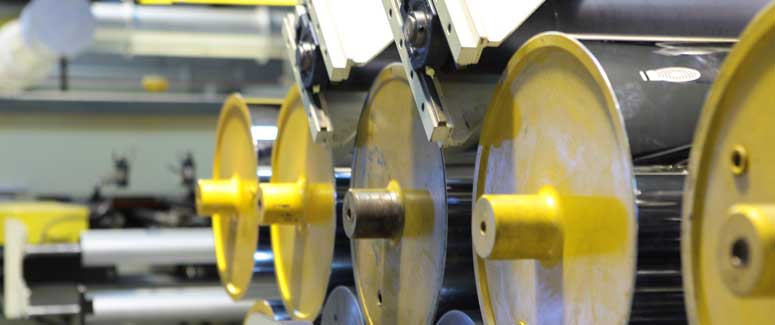

- 3-roll vertical stack.

- 12″ roll diameter.

- Variable speed drive.

- Calendering capability.

#3 – 14 inch and #1 – 16 inch chrome plated P-20 Cloeren sheet dies are available for  customer use.

customer use.